About The Leybold RUVAC WAU1001 Blower

The Leybold RUVAC WAU1001 blower is used in many industries. Roots blowers are used where great volumes have to be pumped, sectors include industrial and chemical processing, waste treatment and disposal, semiconductor manufacturing, paper handling and printing, vacuum packing machines, woodworking and CNC machines, plastic and rubber processing, and R&D.

For this particular client, due to wear and tear, one of their critical vacuum pumps started showing signs of decreased performance, requiring a comprehensive overhaul to restore optimal functionality.

The vacuum blower was experiencing reduced efficiency, noisy operation, and occasional breakdowns. A thorough inspection revealed the accumulation of dust, degraded oil, worn-out seals, and deteriorated components, necessitating a complete overhaul to ensure uninterrupted production.

Service Steps:

Dust Removal:

The initial step involved the meticulous removal of accumulated dust and debris from the external and internal components of the vacuum blower. This was crucial to prevent further damage and enhance the blower’s overall efficiency.

Oil Drain:

The existing oil was drained to facilitate a clean and effective overhaul. The oil analysis helped identify any signs of contamination or degradation that might have contributed to the blower’s deterioration.

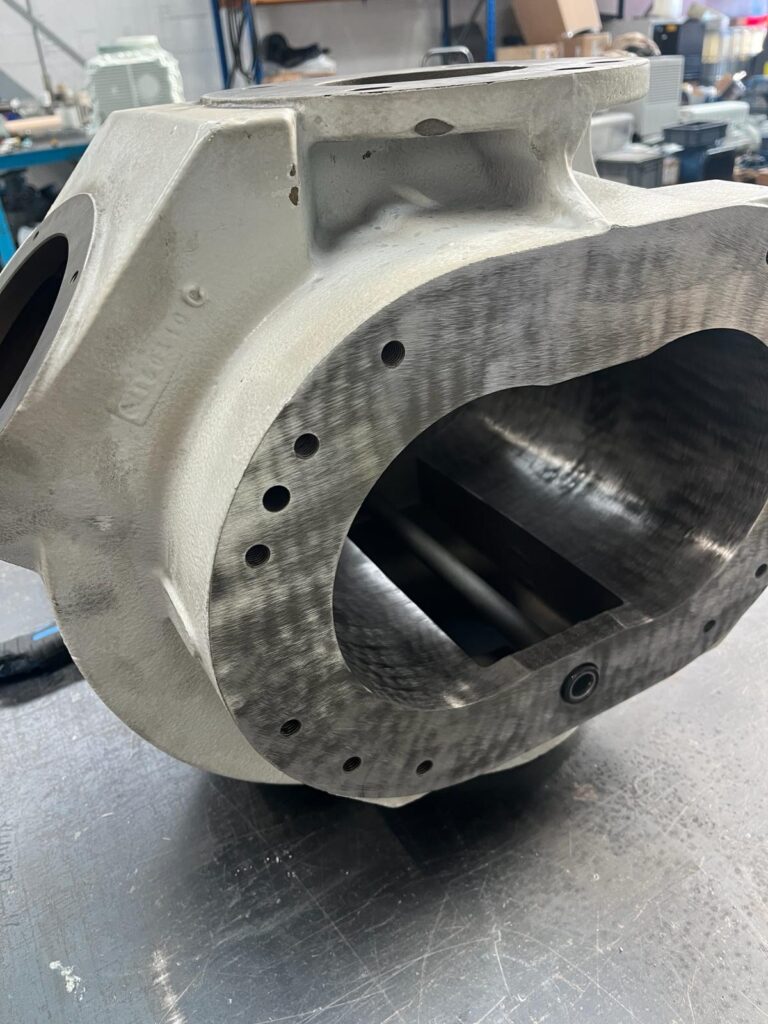

Complete Disassembling:

Every component of the vacuum blower was disassembled, including the casing, rotor, vanes, bearings, and motor. This step allowed for a detailed inspection of each part to identify any signs of wear, damage, or malfunction.

Aqua Blast Cleaning/Dry Blasting:

All disassembled parts underwent a thorough cleaning process using aqua blast cleaning and dry blasting techniques. This ensured the removal of stubborn contaminants, rust, and old coatings, preparing the parts for inspection and refurbishment.

Reassembling with New Components:

After cleaning, the vacuum blower components were carefully reassembled with precision and attention to detail. New seals, O-rings, bearings, coupling, sleeve, and felts were installed to replace the worn-out or damaged parts.

New Oil Replacement:

Fresh, high-quality oil was added to the vacuum blower, meeting the manufacturer’s specifications. This step is essential for lubrication and optimal performance.

Soak Test:

The overhauled vacuum blower underwent a soak test to ensure that all components functioned seamlessly together. This involved running the blower for an extended period to identify any potential issues or leaks.

Motor Check:

The motor, a critical component of the vacuum blower, was thoroughly inspected for wear, electrical issues, and proper alignment. Necessary adjustments and replacements were made to guarantee the motor’s reliability.

Paint:

The vacuum blower casing received a fresh coat of protective paint to enhance its durability and appearance. This step also helps in preventing corrosion and maintaining a clean working environment.

Full Test:

The vacuum blower underwent a comprehensive performance test to verify its efficiency, capacity, and noise levels. This final step ensures that the overhauled blower meets or exceeds the original specifications.

We work with businesses throughout the UK, in all sectors of industry. We are the trusted partner for all our customers and would love to add you to that list.

To find out more about our services head over to our Services page.